According to Quality Assurance Professor Dr. Noriaki Kano, customers have three levels of needs – Expected Needs, Normal Needs, and Exciting Needs. Most companies today excel today with meeting the expected and normal needs. They give the customer their “must-haves” and provide their “wants” for products and services. But, when it comes to Exciting Needs, fewer companies exceed their customers’ expectations and delight them. The Exciting Needs are often what sets companies apart from one another – companies willing to go the extra mile with a product or service or excels in community outreach. This is where sustainability enters the picture.

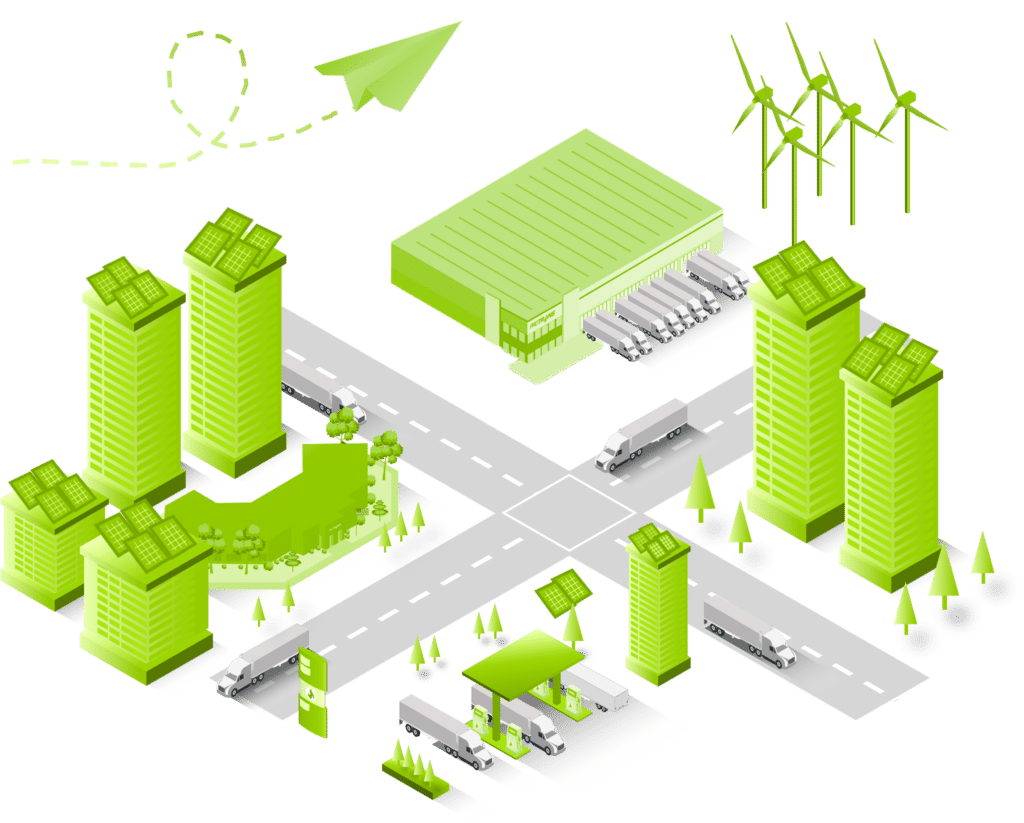

Companies today can differentiate themselves from their competition (and save money in the process) by implementing sustainable practices and procedures in their operations – especially in their supply chains. According to the Sustainable Supply Chain Foundation, supply chains have a greater impact on the environment than any other part of the operation; so by making their supply chains sustainable, companies can do the most good to help protect the environment and set themselves apart from their competition. First – companies should know what a sustainable supply chain is, next, – why they should have one, and finally – how to have one.

What is a Sustainable Supply Chain

Supply chain sustainability are both cost – and environment-saving measures companies can implement in order to be responsible citizens of the world and to offset the environmental impact they cause with their daily operations. These involve both the internal actions of their own company as well as the actions of others in their supply chain. These measures are varied, but many fall within these categories:

| Product Design | Product Development| Material Selection | Manufacturing | Packaging | Transportation | Warehousing | Distribution | Consumption | Return and Disposal |

The goal is net-zero energy expenditure. A sustainable supply chain would be able to create as much energy as it consumes causing a net-zero effect on the environment. This can often be achieved by energy harnessing devices (wind turbine, solar panel, etc.) or by reducing energy consumption throughout the operation.

The net-zero practices often work hand-in-hand with lean theory tools. They ask companies to only do what is necessary to create a product or service and not to exceed that. Companies should perform tasks to their peak efficiency and effectiveness to eliminate wasteful steps, wasting resources, and expending unnecessary energy. They may also direct companies to buy higher quality, longer lasting parts and components to save the environment from overproduction and their bottom lines financially by reducing costs associated with replacing those parts and components. Overall, sustainability focuses on peak stewardship in both resources and finances in an effort to be socially responsible and fiscally viable.

For a supply chain to be successful and sustainable, each member of the chain must be working towards the same goal of achieving sustainability. If one party is not operating to efficiency and effectiveness, it disrupts the entire chain. For instance, a carrier may be using more fuel-efficient tractors to move freight, but if the shipper detains the carrier, the carrier will still contribute more CO2 and exhaust fumes during their wait time than if they could have driven immediately. So, it is important for each supply chain member to be on board to ensure success.

Why Have a Sustainable Supply Chain?

As stated above, the supply chain has the greatest impact on the environment of all business operations; so, in order to be responsible, that is where companies must direct their attention. Some of the best reasons for sustainability include:

• Environmental Factors: Sustainable supply chains help the environment. They can eliminate waste, reduce energy consumption, reduce carbon emissions, and not disturb natural environments or habitats. Many companies today adversely impact the environment, and these measures can help reduce these effects. Factors like pollution or energy consumption are major environmental impacts and can greatly affect local and sometimes global areas. Companies reducing these impacts can help ensure a safe and clean world for themselves and others to come.

• Better Bottom Line: This can result from cost savings from lean management practices in product creation or service performance or in areas like reduced costs in building overhead. Companies can cut costs significantly by reducing wasteful practices and focusing on efficiency. Time is money – and all the time saved improves the bottom line.

• Government Initiatives and Tax Incentives: Another bottom line bolster is the money governing entities offer companies to operate sustainably. The US federal government offers fuel and tax credits to companies that prove eligible for expense deductions related to energy saving initiatives in areas like solar or wind power, as well as other commercial entities. One of the most recent examples is the Emergency Economic Stabilization Act of 2008 – a law that rewards companies for pollution control, alternate energy use, and energy capturing. These reductions and credits also build the overall bottom line for companies in addition to the savings the initiatives themselves bring.

• Sustainability is Equated with Corporate Social Responsibility and Stewardship: This focuses on being a good global citizen as well as providing good public relations opportunities. Customers and suppliers are beginning to require more from their vendors and one of the most scrutinized areas is a company’s environmental consciousness. Companies want to work with others that are committed to giving back and not operating selfishly. Having an environmental focus shows others that a company is committed to a community and not just profits.

• Social Media Effect: Social media is a major factor in word of mouth reviews and instant feedback. Companies not working sustainably will not be able to avoid public opinion of their actions. That opinion will often sway opinions of other clients and customers.

• The Excitement Need is Becoming More Normal: Part of Kano’s model states that all Exciting Needs novelty wears off and they become normal needs. The same is true for sustainability. In the past, environmental impact was not a large concern. The technology did not exist to prevent it. However, today the technology is readily available to make sustainability a reality and more companies expect it from their vendors. Soon, it will be a full requirement for companies, as the market has grown enough for companies to be choosier with their partnerships.

How to Have a Sustainable Supply Chain

Companies have lots of ways of making their supply chains more sustainable. Some organizations like the Port of Los Angeles implemented a several billion dollar infrastructure project to improve its roadways to help with air pollution from truck waiting and congestion. Other carriers like UPS and FedEx are adding natural gas vehicles to their fleets and fueling stations to support them. They also look at smaller, green alternatives like electric vehicles, boats, and bikes for their last mile deliveries. Smaller options might involve adding solar panels or having reusable packing material for shipments instead of disposable materials.

Large or small, each company can contribute to a sustainable supply chain. Companies can evaluate their products’ design and creation, sourcing, packaging, or distribution for starters. If they are not up to sustainability standards, look at ways of implementing a new process or vendor that does meet the standard. Technology is another effective way of improving a supply chain’s sustainability. It can be effective in building maintenance, product creation, load planning, or just about any facet of business. It is able to assist company functions and improve the company’s efficiency.

Some ways logistics managers can implement sustainable practices would be:

• Executive Buy-in – support from the top makes a big difference when implementing large changes. If they approve, logistics managers can go on and make the needed changes.

• Map Current State of Supply Chain Management: Logistics managers should evaluate their current supply chain practices to find waste and develop a plan to eliminate it.

• Investigate New Technology: Companies are making strides all the time with new and innovative technology that makes supply chains more efficient and effective. Companies wishing to be more sustainable should evaluate the new technology options and be willing to innovate their systems when they can.

Dr. Kano discovered that customers had three hierarchies of needs they needed met and that the Exciting Needs were the ones that helped make tie-breaking decisions. Sustainable supply chains are an example of those needs. Sustainability is an environment- and cost-saving measure that shows customers and suppliers that a company is committed to their communities and not just building profits. They care for the world around them. Companies today need these sustainable elements in their supply chain or soon they will be passed by their competition. Also, the benefits outweigh the costs in many respects – such as cost savings, government incentives, and environmental responsibility. Each individual company can find their own method to improve their sustainability from large measures to small ones – what is most important is that they are in place.